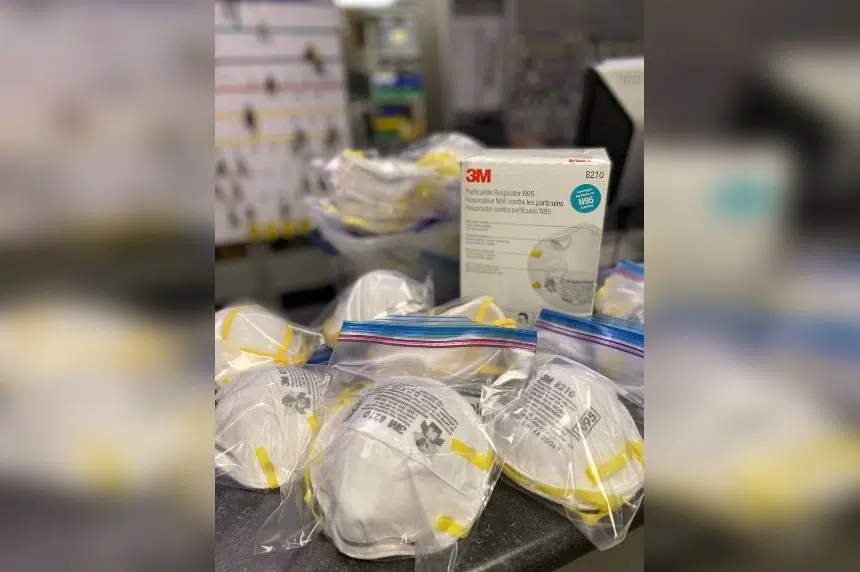

As the world faces supply issues for N-95 medical-grade respirator masks in the middle of the COVID-19 pandemic, the Saskatchewan Health Authority and University of Saskatchewan are striking a deal to create an emergency supply out of masks already in the province.

The Vaccine and Infectious Disease Organization-International Vaccine Centre (VIDO-Intervac) is about to start taking used N-95s and sterilizing them for re-use.

Dr. Volker Gerdts told reporters Thursday afternoon that they’ll be using the same process the virus lab utilizes to sanitize their own rooms and equipment of viral material. It involves a vaporized hydrogen peroxide.

“This is a critical initiative that we hope will save lives and protect our healthcare providers,” he said.

The process was approved by the U.S. Food and Drug Administration on March 28 as an emergency measure, and a lab in Winnipeg confirmed the method’s effectiveness last week.

Gerdts said an individual mask would be able to be re-used five times using the vaporized hydrogen peroxide method, with sterilizations between each use.

He added thousands of masks could be sterilized at a time, with the process taking approximately two-and-a-half days to allow for testing of the masks to ensure they will still work.

VIDO-Intervac could start establishing the emergency supply for the Saskatchewan Health Authority (SHA) as soon as next week.

Representatives from the SHA said in Thursday’s virtual news conference that they are still working to establish national and international supply chains for new masks, but given the challenges presented by the pandemic’s presence around the world, the re-use option will serve an important purpose.

Until Thursday’s agreement with the U of S, the SHA indicated their personal protective equipment (PPE) stockpile could only last for one month.

“The contingency plans are really important,” said Dr. Mike Kelly, co-chair of the SHA’s newly-established PPE task force. “Hopefully we don’t get to the situation where our current supply requires them, but it’s important we have backups to backups to backups.”

Kelly added it’s not clear how long the sterilization process will extend the SHA’s supply stockpile for.

Four existing staff members will be responsible for the sterilization process. Gerdts indicated these are separate staff members from those who are currently working on a potential vaccine for COVID-19.

“These staff members have volunteered to help,” he said. “They have come forward, stepped up and said ‘this is something we can do.’”

Both the SHA and VIDO-Intervac indicated the cost of the sterilization program will be minimal, given it mostly uses existing resources.

As the program moves forward, the teams will also be looking at whether other PPE items such as face shields can be sterilized using the same vaporized hydrogen peroxide process.